top of page

Project Overview

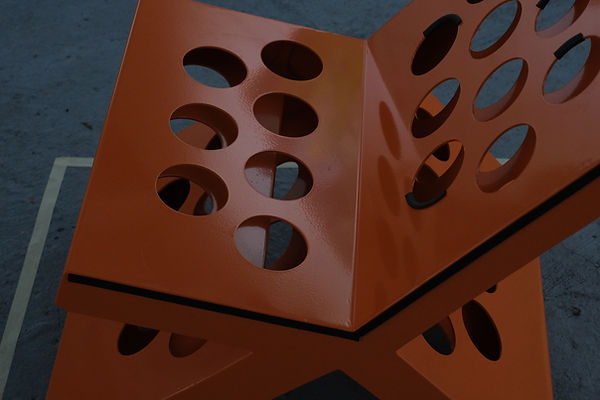

I’ve always enjoyed being hands-on and creating things I love.

Using leftover sheet metal materials, I reverse-engineered and built an artistic chair — turning industrial scraps into something uniquely personal.

CAD Drawing

After Press & Break

After Welding

Art Show Showcase

PROJECT TWO

Reverse Engineering on

“Mini Stove”

Project Overview

Sheet-Metal for the housing + Glass Side Cover

Currently Under Prototype Testing Stage

bottom of page